- #Freecad 3d printing checker how to

- #Freecad 3d printing checker software

- #Freecad 3d printing checker code

- #Freecad 3d printing checker free

When it comes to 3D printing, optimizing your design is crucial for achieving the best possible results.

#Freecad 3d printing checker software

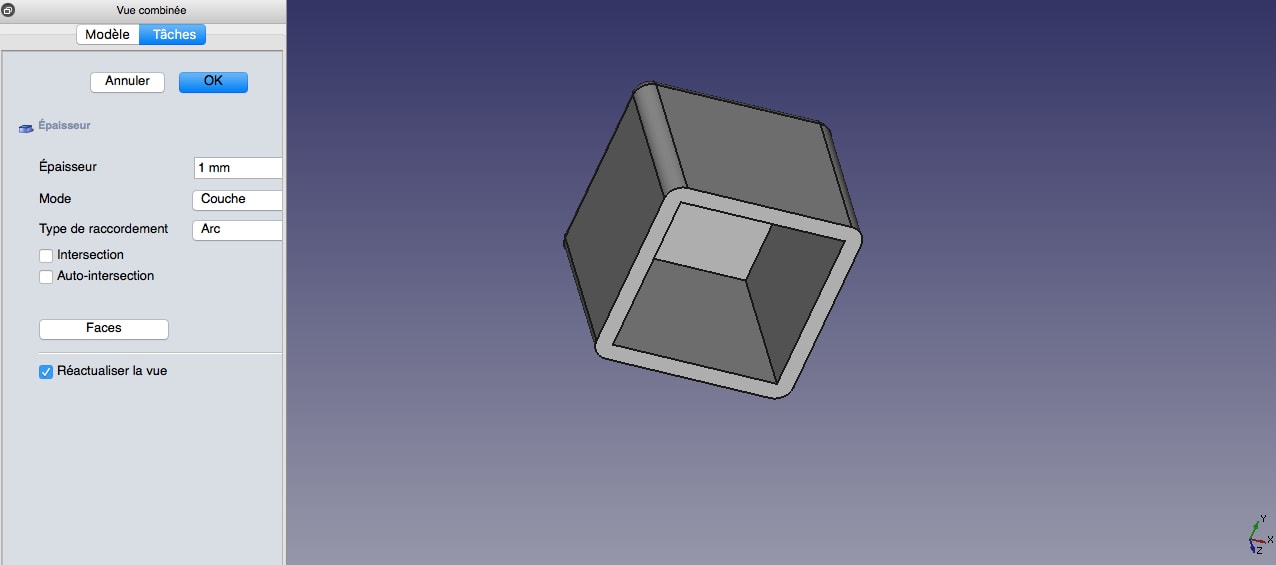

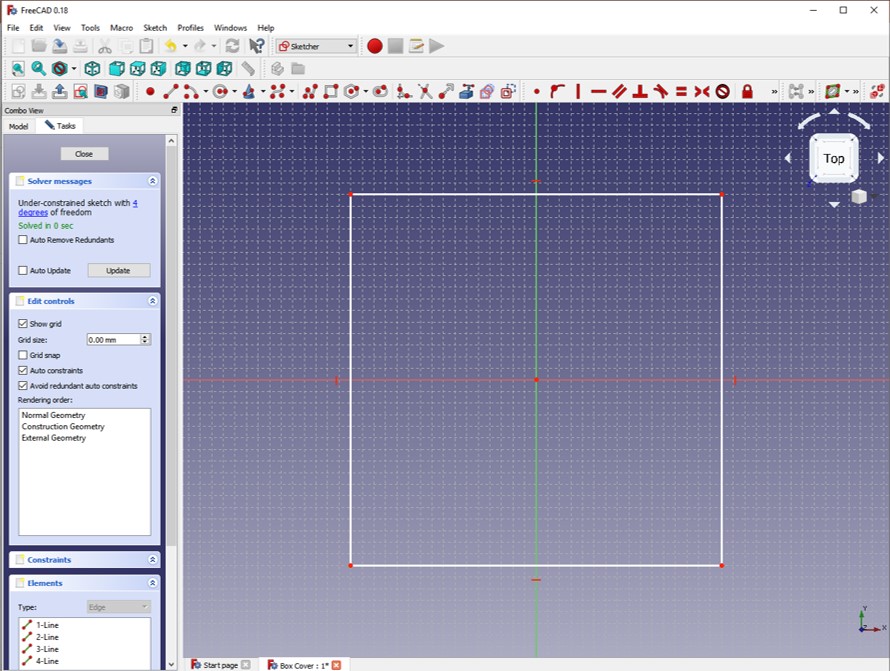

Checking and correcting non-manifold geometry is also important.īy following these design tips, you can create high-quality, customized 3D prints using top open source CAD software for best open source 3D Printers However, there are common design mistakes you should avoid, like using complex geometries or unsupported structures. Creating watertight designs is also crucial for better 3D printing results. Then, use parametric modeling and apply design constraints to give yourself more control and consistency. Start by choosing the right software for your project, considering factors like ease of use and compatibility. To get the best results when using open source CAD software for 3D printing, it's important to follow some key design tips. In summary, CAD software is used to create 3D models, while slicing software is used to prepare those models for 3D printing. It includes a feature called " hollowing " which can make 3D prints more lightweight and cost-effective, while still maintaining structural integrity. Slicing software also allows users to adjust various printing settings, such as layer thickness, infill density, and print speed.įlashforge's slicing software, FlashPrint, is great for 3D printing. Slicing software takes the 3D model and "slices" it into layers, which the 3D printer uses to create the physical object. On the other hand, slicing software is used to prepare a 3D model created using CAD software or downloaded from the internet for 3D printing. CAD software is commonly used in engineering, architecture, product design, and many other fields. It allows users to create and modify designs in a virtual environment before physically creating the object.

#Freecad 3d printing checker free

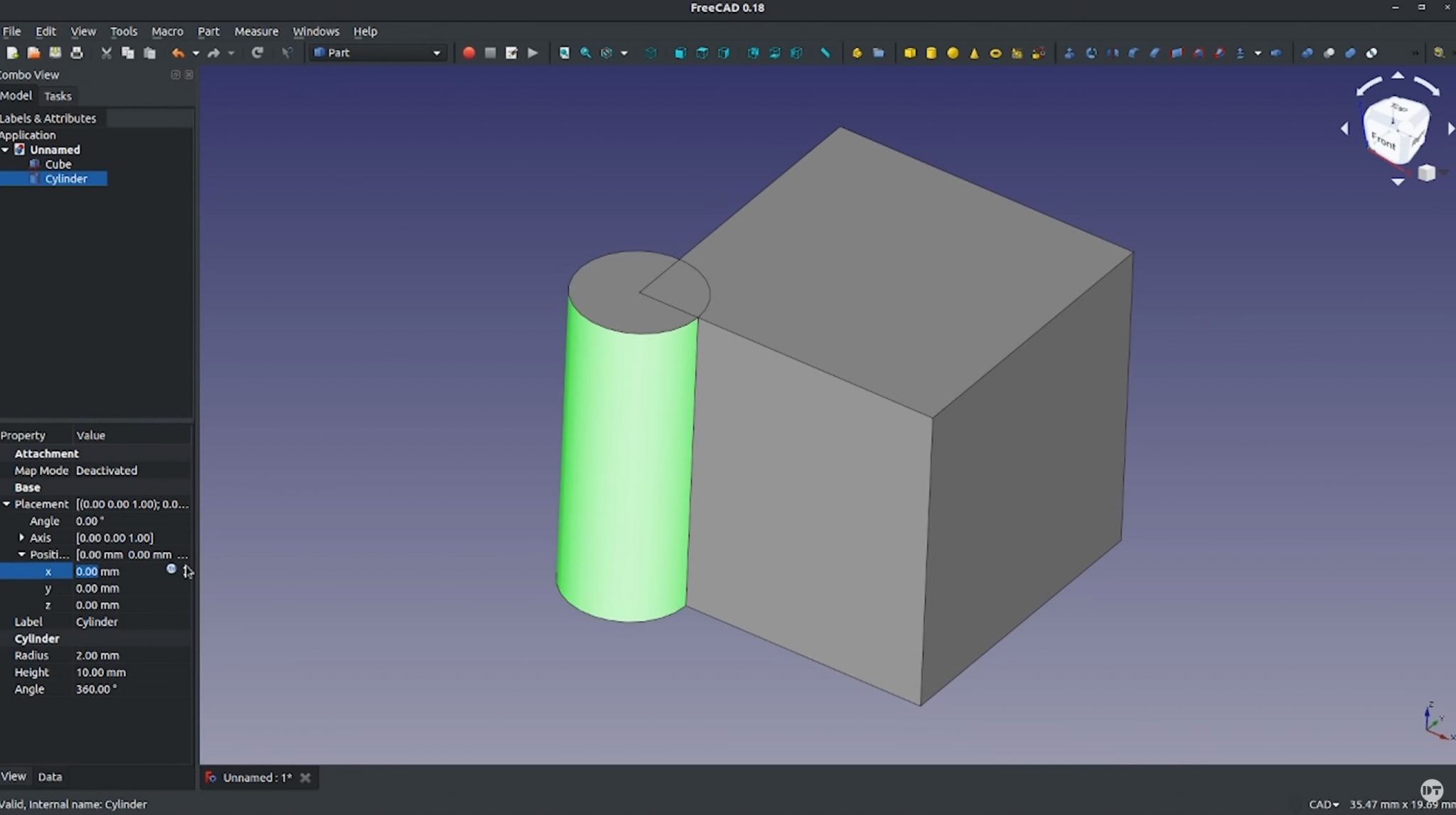

Some free CAD programs for 3D printing include FreeCAD, OpenSCAD and Blender.įreeCAD Software What is the difference between CAD software and Slicing software?ĬAD (Computer-Aided Design) software is used to create 3D models or designs of objects on a computer. Additionally, open source CAD software often has strong community support and resources, including forums, tutorials, and libraries of pre-made models. Open source CAD software has become increasingly popular in recent years due to its flexibility, cost-effectiveness, and ability to support a wide range of file formats. This means that users can customize the software to suit their individual needs, and contribute to the development of the software by fixing bugs, adding new features, and improving its overall functionality.

#Freecad 3d printing checker code

Open source CAD software refers to CAD software whose source code is openly available to the public, allowing anyone to view, use, modify, and distribute it freely. So let's dive in and unleash your creative potential with open source CAD software and 3D printing!

In this ultimate guide, we'll cover the best open source CAD software programs for 3D printing in 2023, as well as ips for designing and printing your 3D models.

#Freecad 3d printing checker how to

So why not get ahead of the curve and learn how to use open source CAD software for 3D printing like a pro ? If its wireframe is not precisely determined, the software of the 3D printer will have difficulty in reading the file, so it may not succeed to print the object.Are you ready to take your 3D printing game to the next level? Whether you're a seasoned pro or just starting out, one thing is clear: open source CAD software is the key to unlocking your creative potential.ĭid you know that in 2022, the global 3D printing market size was valued at $13.78 billion USD? And that's just the beginning - experts predict that this figure will skyrocket in the coming years. So, if a 3D model contains non-manifold modeling errors, will look different when rendering the 3D file. During this procedure, its edges and its vertices are being specified and the object is being drawn as a set of lines at the location of every single edge. Though, when 3D rendering, the 3D model is being converted into a 3D frame model. Once you are in the 3D modeling software, these kinds of errors may not be visible, as you are dealing with the shape and the volume of the 3D model as a whole. In addition, errors that create a shape without volume should be fixed or eliminated at all. It may also happen that faces attached to each other are connected to a single point, and not to a single edge. This is because during the creation of a 3D model some operations may create unattached surfaces or they may divide a surface. This is a very common error that may occur while creating a digital object.

A vector field of normals on a surface – Image from Wikipedia

0 kommentar(er)

0 kommentar(er)